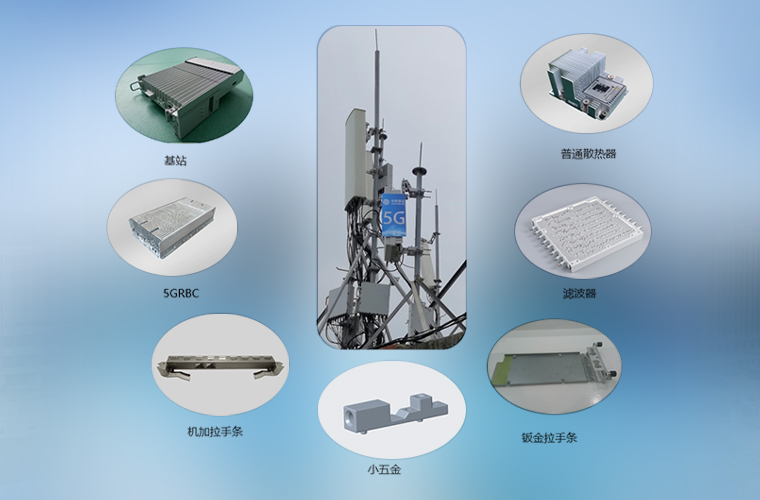

Product Development

Our products cover multiple fields such as communication, new energy vehicles, energy storage, semiconductors, and heat sinks. With exquisite craftsmanship and years of accumulated rich experience, we can flexibly design and plan typical structures and processes according to the performance requirements of our products, ensuring the best balance between performance, quality, and reliability; Through CAE design simulation analysis and FMEA, potential failure modes can be systematically identified to reduce product failure risks, ensuring that every step of the product from conceptual design to mass production is strictly controlled, and the entire design, manufacturing, and testing process is completed in one go.

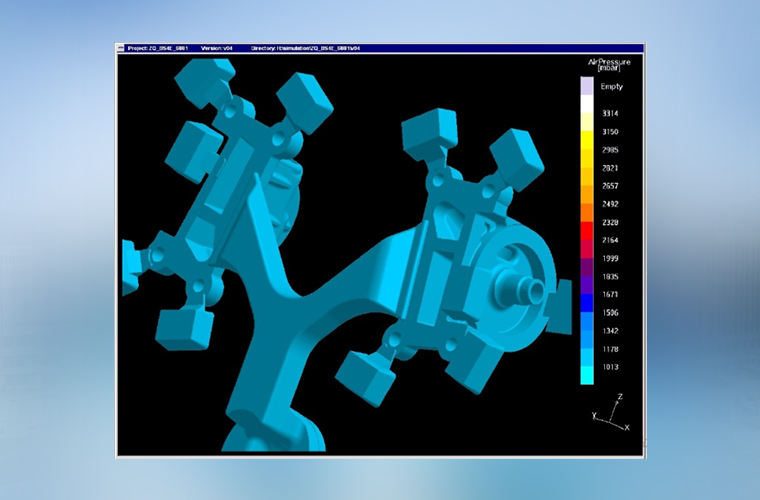

Mold Development

We have a professional die-casting mold and hardware mold design team, equipped with internationally leading MAGMA, JSCASTING, FLOW 3D and other mold flow analysis software, as well as more than 100 advanced mold production and manufacturing equipment and testing equipment, including but not limited to German Hammer five axis machining center, Japanese Shadick slow wire, 3D blue light scanner and X-Ray, etc; We have complete independent design capabilities for complex high-pressure casting molds (including integrated die-casting), and can efficiently carry out design simulation and precise control of every design detail. We can provide customers with one-stop services from design to manufacturing and testing, efficiently designing and manufacturing high-precision and high-quality molds.

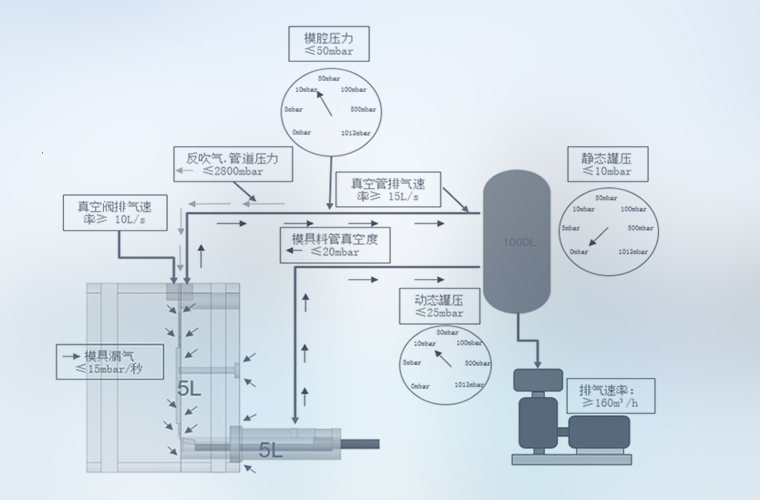

Process Development

The company has been deeply engaged in the field of mechanical processing for more than 30 years, with profound technical accumulation and innovation strength. It has built a comprehensive and high-level technical system in the field of process development, including but not limited to high-pressure casting technology, precision machining technology, surface finishing technology, high-precision automated assembly technology, intelligent dispensing technology, flexible sheet metal technology, friction stir welding and other special process technologies, as well as various non-destructive testing technologies. It can provide customers with a one-stop experience from process design to production manufacturing and testing.

Talent Leader

The company is based on a global perspective, actively introducing high-end technical talents and senior experts, vigorously cultivating internal backbone, and building a high-quality professional talent team. On this basis, the company has hired National May Day Labor Medal winners, senior engineers, and Japanese mold experts as technical consultants and chief engineers, and has more than 10 senior engineers with profound technical backgrounds and rich practical experience in their respective fields, fully exerting their professional leadership role; At present, the proportion of R&D personnel in the company has exceeded 10% of the total number and continues to increase, providing solid technical support for the company's technology research and product innovation.

Joint Laboratory

The company aims to focus on the cutting-edge exploration and industrial application of friction stir welding technology, providing innovative power for high-end equipment manufacturing. It has jointly established a friction stir welding joint laboratory with Suzhou Aerospace Engineering Equipment Co., Ltd., a subsidiary of China Aerospace Science and Technology Corporation. The laboratory is dedicated to tackling key technical challenges such as thick aluminum alloy welding and real-time monitoring and control of flexible weld seam deviations, providing intelligent and efficient welding solutions, and helping high-end equipment manufacturing move towards higher levels.

Invention patent

The company owns 108 intellectual property rights, including 100 utility model patents and 8 invention patents. It covers the company's core products such as communication structural components, radiators, new energy vehicles, charging piles, as well as key technical fields such as ultra vacuum die-casting technology, precision machining technology, and airtight detection technology, fully reflecting the company's depth and breadth in technology research and development. In addition, we have 21 patents in the application stage and plan to export no less than 12 intellectual property rights annually, indicating that our innovation pace has never stopped and continues to inject new vitality into the company's technological reserves and future development.