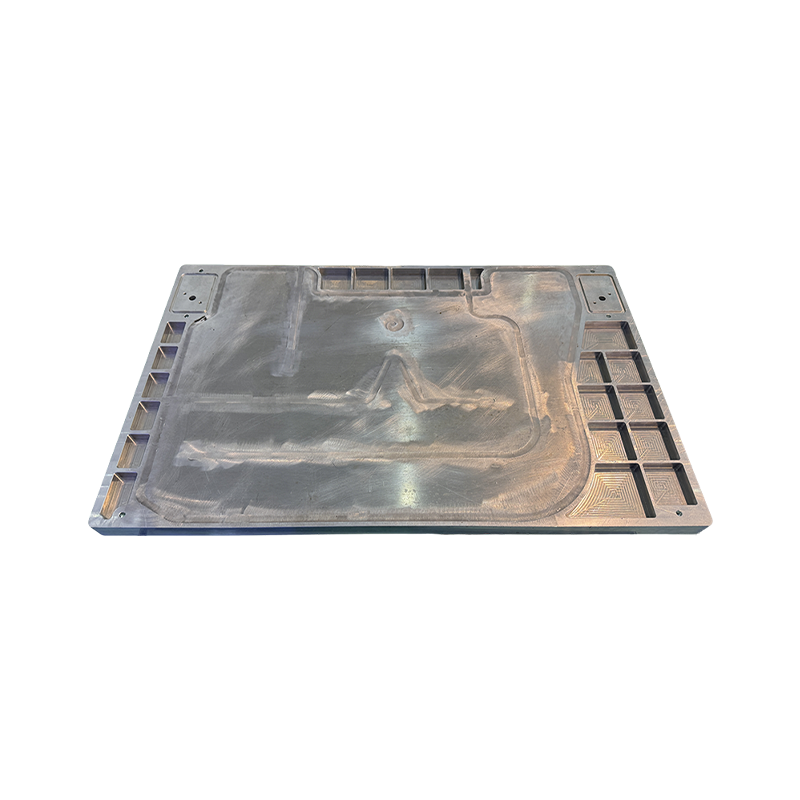

Wind turbine liquid cooling module

As a critical component in fast-charging EV charging stations, the liquid cooling system primarily absorbs and dissipates heat generated during charging through a circulating fluid. The efficient heat transfer via liquid flow maintains the internal temperature within safe operational limits, ensuring high charging power and enabling rapid charging. Advanced manufacturing processes, including friction stir welding (FSW) and non-destructive testing (NDT) techniques (such as phased array ultrasonic testing and helium leak detection), are employed to guarantee optimal part sealing.

Process Features:

High-vacuum die-casting + high-pressure point cooling + automatic mold temperature control ensure porosity-free cooling channels in the die-cast components.

Friction stir welding (FSW) with constant pressure control + hydraulic anti-deformation fixtures + thermal straightening achieves a large-surface flatness of ≤0.5mm.

High-pressure cleaning line + 50MPa point-to-point high-pressure cleaning ensures product cleanliness: CCC = Mcp (E-K10) / EX = 500μm (ISO 1623).

Weld offset detection + phased array testing guarantee a helium leak rate of ≤1×10⁻⁶ mbar·L/s, ensuring absolute sealing integrity.