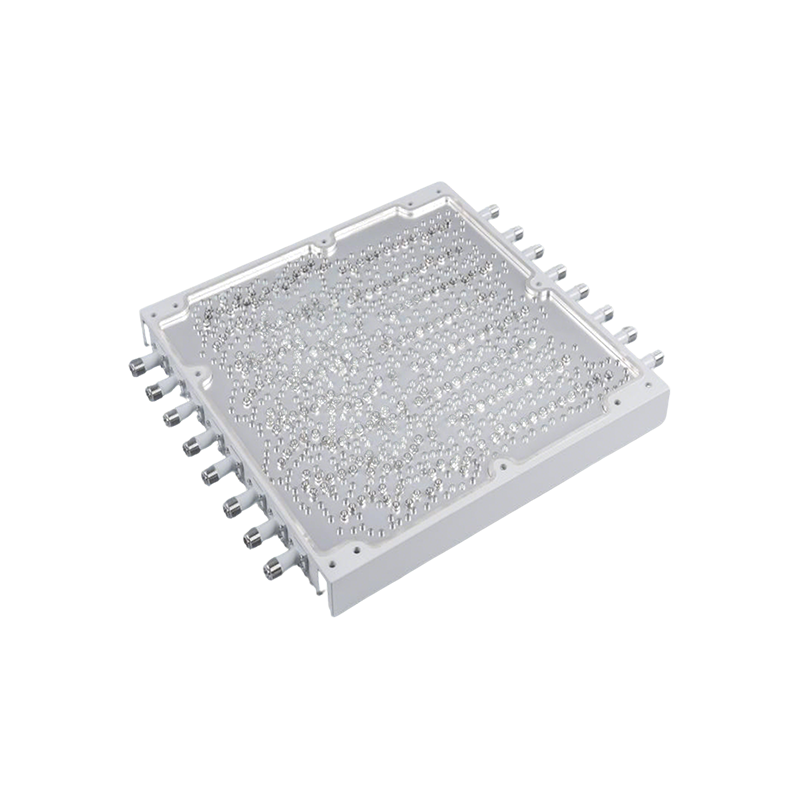

filter

Product Name: Filter

Usage scenario: A filter is essentially a frequency selection device that allows signals within a specific frequency range to pass through while suppressing or attenuating signals at other frequencies. Its applications are almost ubiquitous in all fields of electronics and communication.

Process characteristics:

1. Cavity Milling: Using vertical or horizontal machining centers, the shape and depth of the resonant cavity are accurately machined through contour milling. This is the most crucial step, as the size of the cavity directly determines the center frequency of the filter.

2. Precision Drilling: Processing tuning screw holes, input/output interface holes, etc. The requirements for the verticality, positional accuracy, and aperture tolerance of the hole are extremely high (often within ± 0.01mm).

3. Tapping: Processing high-precision internal threads for tuning screws.

4. Face Milling: Processing the installation joint surface of the cover plate, requiring extremely high flatness and surface smoothness to ensure airtightness after installation.

Challenges and Solutions:

▪ Thin walled deformation: The filter cavity wall is usually thin and prone to deformation during processing. The strategy of high-speed milling, small cutting depth, and multiple cutting paths should be adopted, and the clamping scheme should be optimized.

▪ High consistency requirement: During mass production, it is required that the electrical performance of each cavity be consistent. This depends on high stability machine tools, specialized cutting tools, and mature machining process parameters.